YAG Machined Part Tips & “Rules Of Thumb”

For silicon wafer machining, apply positive photo resist or ask Questech to spray positive photo resist on wafers; this leaves less slag and dust on surface and protects delicate circuits.

Silicon wafer cut size is limited to 12-inch diameter.

Rubber cut size in limited to 12 inch x 12 inch.

Thin metals, solder materials, foils and PC board materials are limited to 7 inches x 8 inches cut size.

Silicon less than or equal to .010 inches thick is Technikote mounted on alumina carriers, machined and shipped mounted. De-mount using hot water.

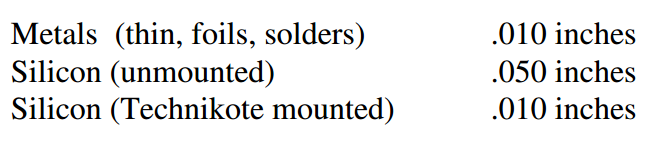

To minimize cracking, separate cut features by the following amount:

Material waste area allowance (perimeter)

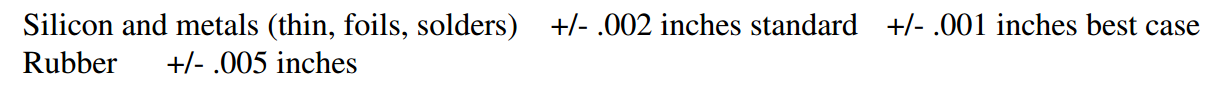

Cut part tolerances:

Smallest drilled hole: .004 inch diameter entry side

Smallest cut rectangle: .006 inches x .006 inches

Cut thickness capability:

Ablation: feature path is .004 inch minimum.

If pin gage measurement is required, specify on part drawing

Optical alignment considerations: difficulty is encountered aligning to beveled (radiused) edges of silicon wafers and to significantly raised features. This adversely affects cut placement accuracy.

Solder preform materials less than .003 inches thick will be typically slightly bent from handling process.